The definitive guide to longarm quilting machine needles

Needles are one of the most critical tools in a quilter’s sewing box. Choosing the right needle for the thread, fabric and batting you’re using can mean the difference between a fabulous quilt and one filled with tension issues, broken threads, and batting pokeys!

Choosing the right needle

New longarm owners quickly discover that longarm needles are very different from the ones they’ve used for piecing quilts.

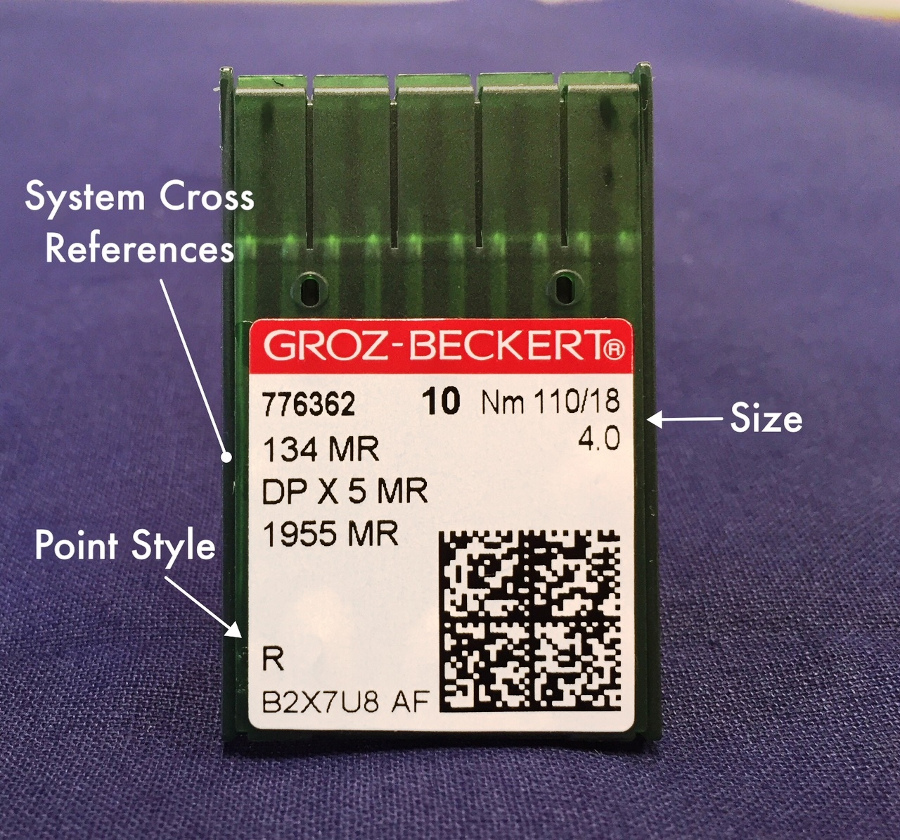

Industrial needles come in many configurations to fit different machines. Four main components identify a needle – the needle system, point style, needle size and coating. The easiest way to ensure you’re getting the right needles is to buy them directly from your machine manufacturer or an authorized dealer. If you are buying from a different vendor, verify the needle system your machine uses, and compare it to the system references on the label to make sure they will work. APQS machines use the Groz-Beckert needles pictured below.

All the numbers and letters on a needle package can be confusing. APQS machines use “MR” needles, which means “multi-directional.” These needles resist bending and have a very deep, extended scarf (the notched area behind the needle), which allows tighter hook placement for superior stitches. In addition, the needle eye and long groove above it are specially designed to reduce thread twist and keep the thread loop formed when changing directions. Those features allow APQS owners to use all types of threads very successfully.

Letters on the package indicate its point style (R = regular round point, FFG = light ball point). The R tip is most common for lockstitch sewing and works particularly well on woven fabrics and coated fabrics, which is why APQS recommends sharp point needles for its longarm machines. Some quilters wonder about using ball point needles on knit fabrics like t-shirt quilts; however, an R point works well since the t-shirts are typically stabilized. An R point pierces the multiple layers better, resulting in fewer skipped stitches.

Titanium needles have been popular with machine embroidery enthusiasts and longarm quilters have started to take notice. These needles have a higher hardness than regular needles and have a higher wear resistance. Titanium needles are usually gold-colored. While these needles may not need changing as often, their increased hardness can result in greater damage to the quilting machine or quilting fabric if they break.

For this reason, APQS recommends standard Groz-Beckert MR needles with chromium coating rather than titanium needles.

Size matters

Longarm quilters can move the machine over fabric much faster than anyone can push fabric under a stationary needle. This makes the needle bend considerably more as the fabric and batting pull on it. Small, thin needles would break easily under this stress. Therefore, longarm machine needles must be much larger than regular sewing needles to reduce the needle flex. Over flexing the needle can cause flat stitches on the back, “railroad tracks” and generally poor tension.

Thread thickness and type also have a big impact on needle selection. The thread should be cradled in the long groove running down the front of the needle. If the needle is too small for the thread thickness, the thread will not stay aligned with the needle’s eye, causing shredding and breakage. The top thread passes through the needle eye 40-70 times during stitch formation, so the eye must be large enough to easily let the thread slide through. If you have trouble threading the needle (and you know it’s not just your eyesightJ) then the needle is too small for your thread!

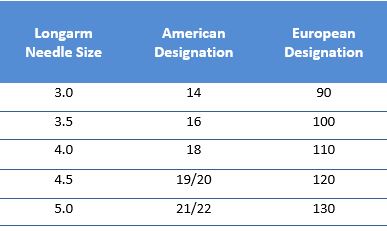

The chart below illustrates how longarm needle sizes are cross-referenced. APQS machines are closely timed to a 4.0 industrial needle, giving you the flexibility to move to a 3.5 size for thin threads like 100-weight silk, 60-weight bobbin-weight thread or ultra-thin invisible thread. Or you can move up to a 4.5 needle size for thicker threads like 30 or 40-weight cotton, polyester, or variegated blends.

The standard 4.0 needle easily handles the most common threads ranging from 40 to 60 weights in all types of fibers. Close timing prevents skipped stitches and helps provide excellent stitch quality with all sorts of thread.

Proper needle insertion

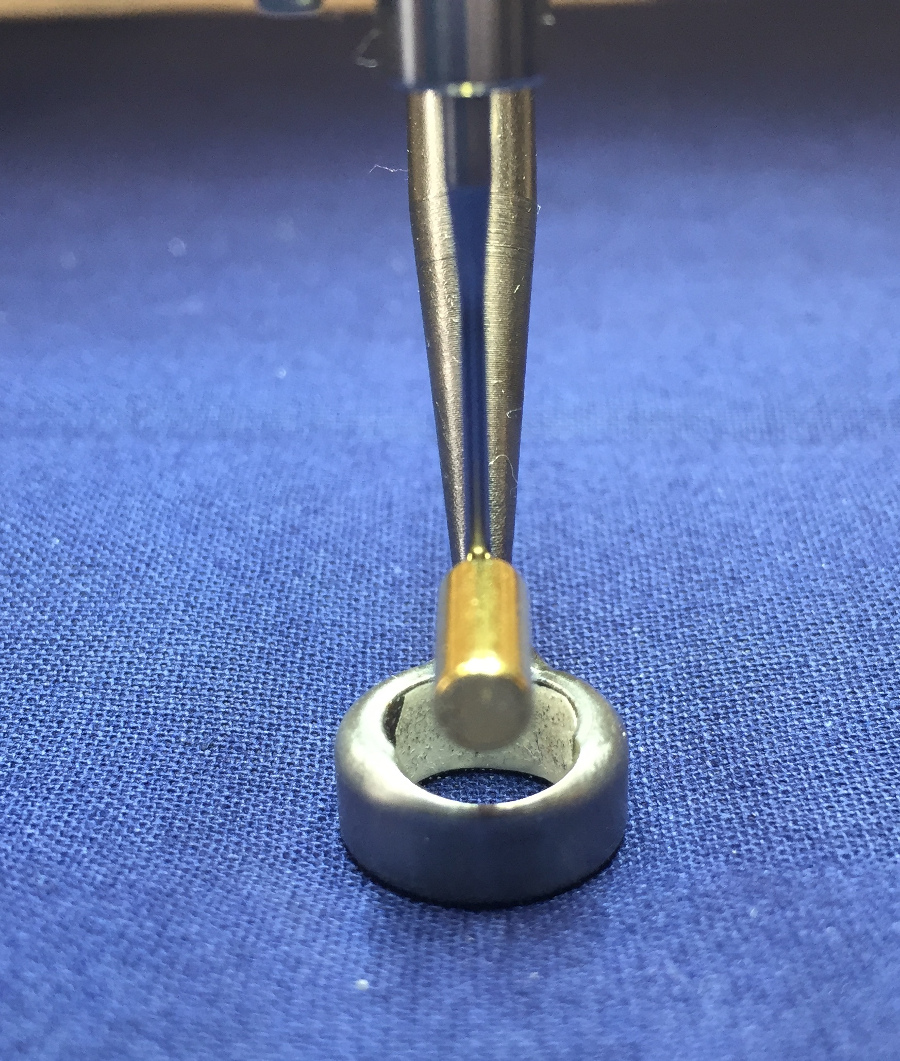

The round shank on industrial needles presents a challenge for inserting them correctly. The needle eye must be straight so that the thread loop formed behind it stays open and the hook can grab it during stitch formation. You can use a magnet alignment tool on your needle to quickly and accurately position your needle.

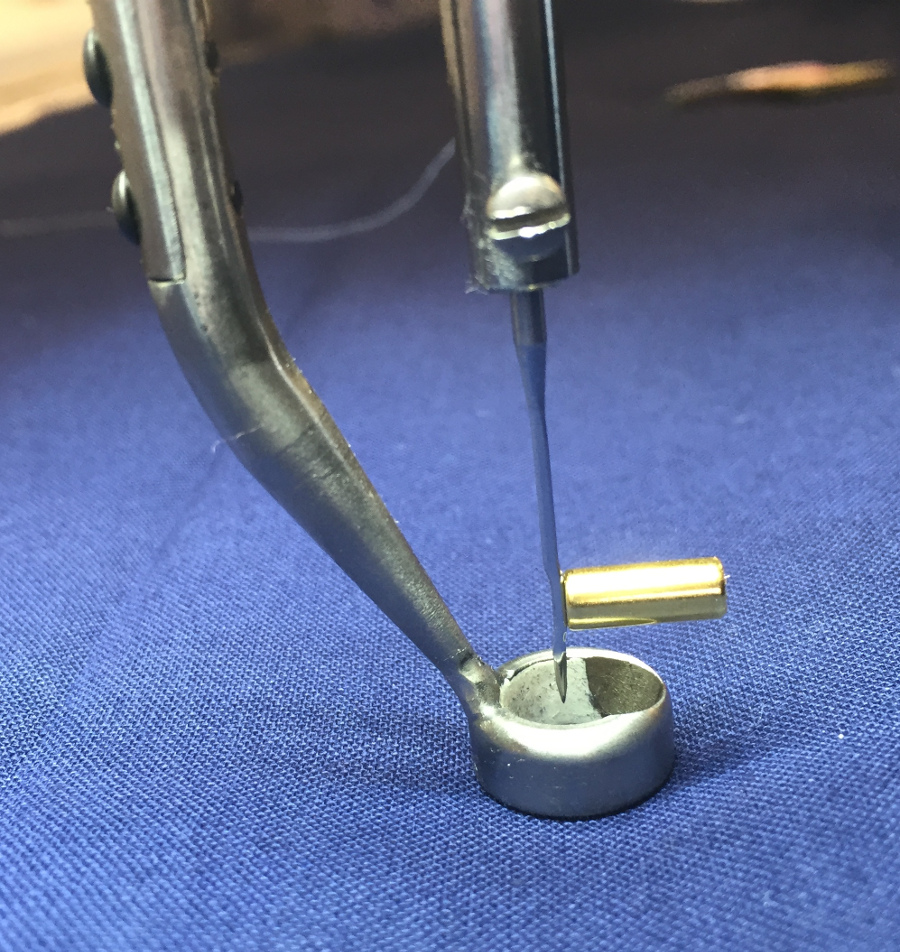

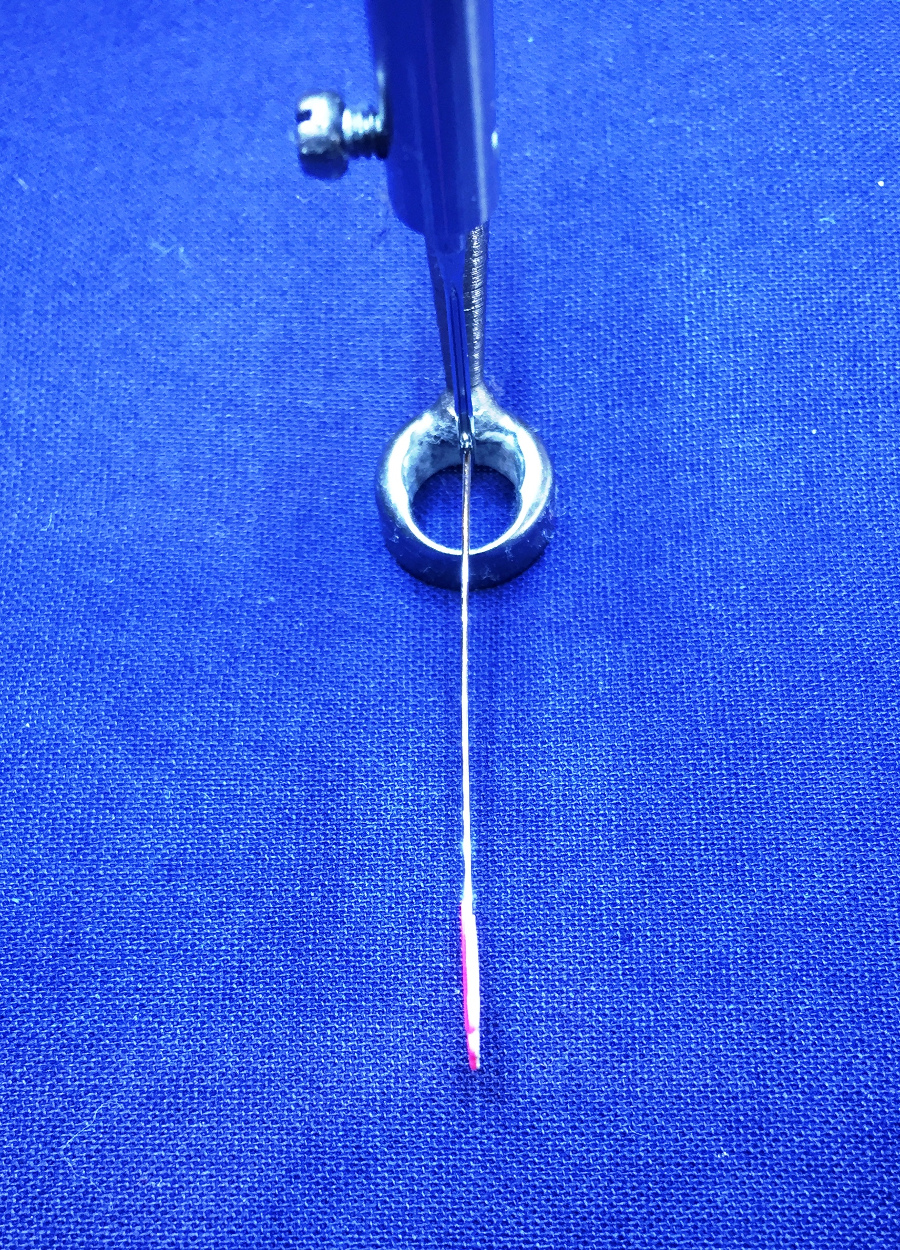

Or you can insert a straight pin into the needle’s eye to check its position as you tighten the needle screw.

Sometimes quilters will turn their needle slightly to the left if a thread’s twist is affecting the stitch quality or causing shredding. This aligns the thread loop with the hook just a little sooner. If the loop starts to collapse, the hook may only pierce part of the loop. For best performance, keep the needle straight for most threads.

How often should a needle be changed

A new needle is very cheap insurance against batting pokeys, torn fabric, poor tension or thread breakage. While the sheer size of longarm needles makes them sturdier than domestic needles and they could potentially last through several projects, you can save yourself lots of frustration by changing the needle frequently. If you quilt for others, using a new needle on every quilt is a positive selling point for your services – it tells your customers you care about their quilt!