Quilting the Quilt: Are you ready for a longarm?

Download this article as a PDF

Is your stash of unfinished quilt tops starting to rival your stash of fabric?

Do you want to machine quilt your projects but you’re tired of squeezing big quilts through a tiny sewing machine opening?

Are you fed up with crawling around on the floor to baste your quilt layers together?

Do you want to say that you made your quilt from start to finish?

If you answered “yes” to any of these questions, it may be time to add a longarm quilting machine to your quilting studio.

A longarm quilting machine can bring you years and years of fun as you whittle your quilt top stash down, making room for more projects. It is an investment that could last a lifetime, so you’ll want to look at the machine’s warranty as well as the company’s reputation for customer service, education and support. This will ensure you choose the best machine for your needs. You don’t want to have an unexpected malfunction in the middle of quilting your daughter’s wedding quilt, only to discover that the machine’s electronic warranty expired six months earlier.

Longarm technology has come a long way since I purchased my own longarm almost 25 years ago. Stitch regulators didn’t exist so I had to focus on my design while also trying to move the machine at a very steady pace to keep my stitches consistent—not an easy task!

Thanks to stitch regulation, the learning curve for longarm quilting has been drastically reduced. Instead of worrying about how fast or slow you’re moving, you can concentrate strictly on creating your design. Virtually all longarm machines now have some type of stitch regulator. The key is learning how to identify a good stitch regulator from a poor one so your stitches don’t look like you have no stitch regulator at all.

All longarms do a decent job of regulating your stitches when you make swooping designs like meandering or loops. But if you’re investing in a longarm, you’ll want a machine that regulates the stitches all the time, not some of the time. To evaluate this function, make designs that change directions or have sharp points during your longarm test drive.

A good stitch regulator will place a stitch at a direction change to make your points nice and crisp, and then it will immediately resume consistent regulation as you move in another direction.

A stitch regulator that makes longer stitches as you begin sewing, rounds off points, or leaves a long stitch after changing direction isn’t really doing its job.

Next look for a machine that is simple to use and easy to maintain. You want to be able to turn on the machine and go when the mood strikes. It’s not fun to have to get out the operating manual because the machine’s controls are too complicated or you have to go through lots of maintenance steps before beginning. Look for easy oiling points and controls that are simple to understand so you spend time quilting and not reading directions or being a mechanic.

A simple table design will create less stress and speed up quilting during loading process. Longarm machines come in different table lengths to accommodate different quilt widths as well as different throat sizes—anywhere from 18 to 30 inches or more. No matter what throat size you choose, you want to be able to use all the available quilting space from beginning to end. Look for a 4-roller table design that keeps the finished quilt section from encroaching on your quilting space. With some table set-ups you must raise the roller where the finished quilt gathers as you advance the quilt, causing you to lose valuable quilting space as you go. You don’t want to start out doing a 12-inch block design and then find out you only have room to do half of it when you reach the bottom of the quilt.

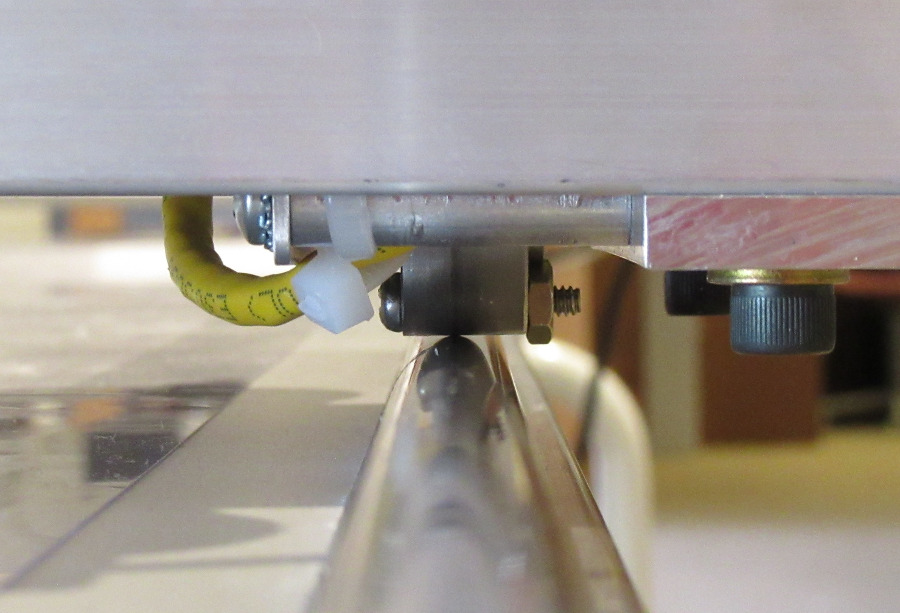

Look for a machine that’s lightweight and glides easily so that you can quilt for longer periods without feeling fatigued. A seamless track system with minimal friction points helps with that.

One-piece rails also prevent hiccups and wiggles in your design which can happen if the machine bumps over junction points in sectional table rails. Choose a table that’s easy to assemble with solid, sturdy legs, rollers, and rails. Unlike jointed rollers, one-piece rollers keep your quilt from sagging in the middle, alleviating pleats and tucks in the backing fabric.

If you’re thinking, “It takes up too much room,” you’ll be surprised to learn that a longarm quilting machine that can finish a queen-size quilt takes up only 50 square feet of space. That’s not much bigger than a full-size couch. Even after adding enough room to maneuver around the machine you’ll only need about 96 square feet.

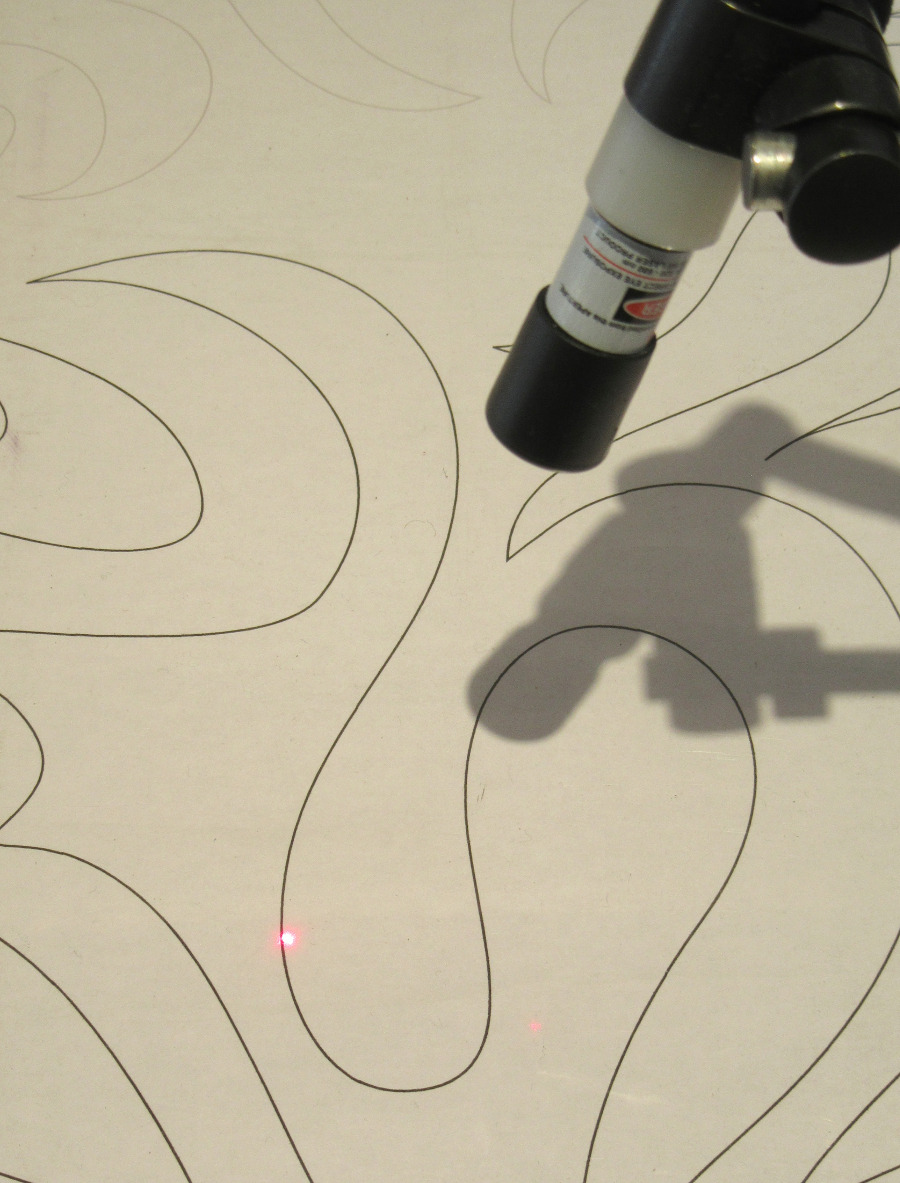

If you’re concerned you don’t have the talent or skill to use a longarm, don’t be. If you can trace, you can use a quilting machine. Thousands of paper designs called “pantographs” are available. These designs are printed on a long roll of paper placed on the table side of the longarm.

Look for a machine with a built-in laser, which will guide you as you trace the design and stitch it on the quilt with the quilting machine.

Quilters have thrived, thanks to early quilting bees through small quilt groups, guilds, and networking. Thanks to social media and the Internet, quilters can continue sharing and learning from others on a global scale. That same camaraderie and support will be very helpful when you enter the world of longarm quilting.

Talk to others about their machines, their likes and dislikes, and their personal experiences with the manufacturer. Check out message boards, Facebook pages, and even the company’s website to find out how they interact with customers. Look for ample educational opportunities, open forums for sharing questions and ideas, quality support and superior customer service.

If you aren’t sure a longarm fits within your budget or you currently “quilt by check,” you’ll be surprised that you can find a high quality longarm with topnotch features at an affordable price. Take a look at what you currently pay others to finish your quilts and apply that toward owning your own longarm. The average fee for overall quilting in the U.S. is 2 cents per square inch, which means a queen-size quilt runs about $180 (labor alone). If you quilted just two quilts a month instead of sending them out to be quilted, you’d have a top-of-the-line machine paid in only 5 short years.

But be careful—if your friends discover your secret, you may unexpectedly find yourself in business before you know it!